Textiles are identified as a key value chain in the EU circular economy action plan and will be addressed in the forthcoming European Commission’s 2022 EU strategy for sustainable and circular textiles and EU sustainable products initiative. This briefing aims to improve our understanding of the environmental and climate impacts of textiles from a European perspective and to identify design principles and measures to increase circularity in textiles. It is underpinned by a report from the EEA’s European Topic Centre on Circular Economy and Resource Use available here.

1. Production, trade and consumption of textiles

Textiles is an important sector for the EU economy. In 2019, the EU textile and clothing sector had a turnover of EUR162 billion, employing over 1.5 million people in 160,000 companies. As was the case for many sectors, between 2019 and 2020, the COVID-19 health and economic crisis decreased turnover by 9% for textiles as a whole and by 17% for clothing (Euratex, 2021).

In 2020, 6.9 million tonnes of finished textile products were produced in the EU-27. EU production specialises in carpets, household textiles and other textiles (including non-woven textiles, technical and industrial textiles, ropes and fabrics). In addition to finished products, the EU produces intermediate products for textiles, such as fibres, yarns and fabrics (Köhler et al., 2021).

The textiles sector is labour intensive compared with others. Almost 13 million full-time equivalent workers were employed worldwide in the supply chain to produce the amount of clothing, textiles and footwear consumed in the EU-27 in 2020. This makes the textiles sector the third largest employer worldwide, after food and housing. Most production takes place in Asia, where low production costs come at the expense of workers’ health and safety.

Textiles are highly globalised, with Europe being a significant importer and exporter. In 2020, 8.7 million tonnes of finished textile products, with a value of EUR125 billion, were imported into the EU-27. Clothing accounts for 45% of imports in terms of volume, followed by household textiles, other textiles and footwear (Eurostat, 2021a). The EU imports mainly from China, Bangladesh and Turkey, and exports mainly to the United Kingdom, Switzerland and the United States (Euratex, 2020).

Consumption

European households consume large amounts of textile products. In 2019, as in 2018, Europeans spent on average EUR600 on clothing, EUR150 on footwear and EUR70 on household textiles (Köhler et al., 2021; Eurostat, 2021b).

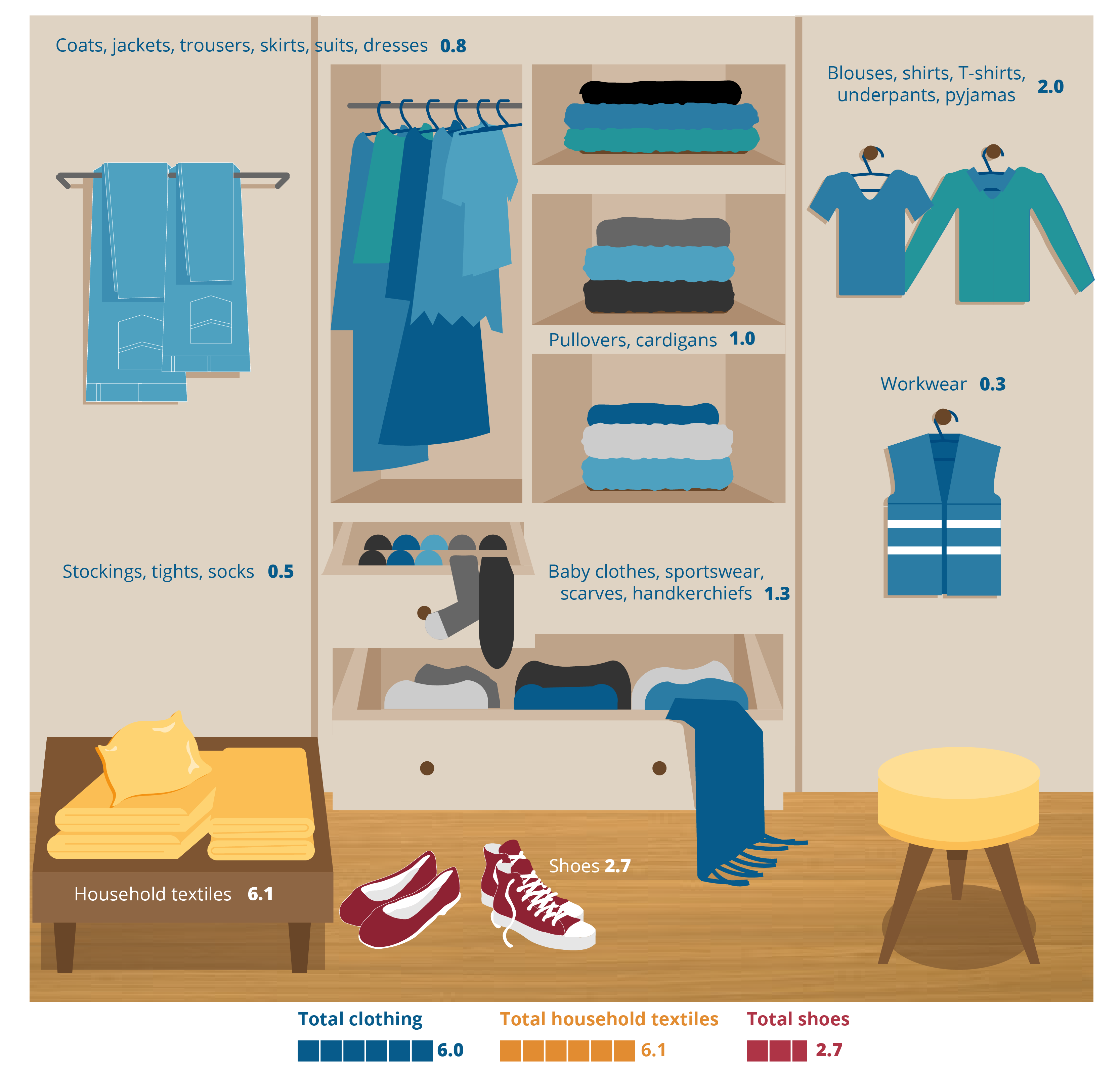

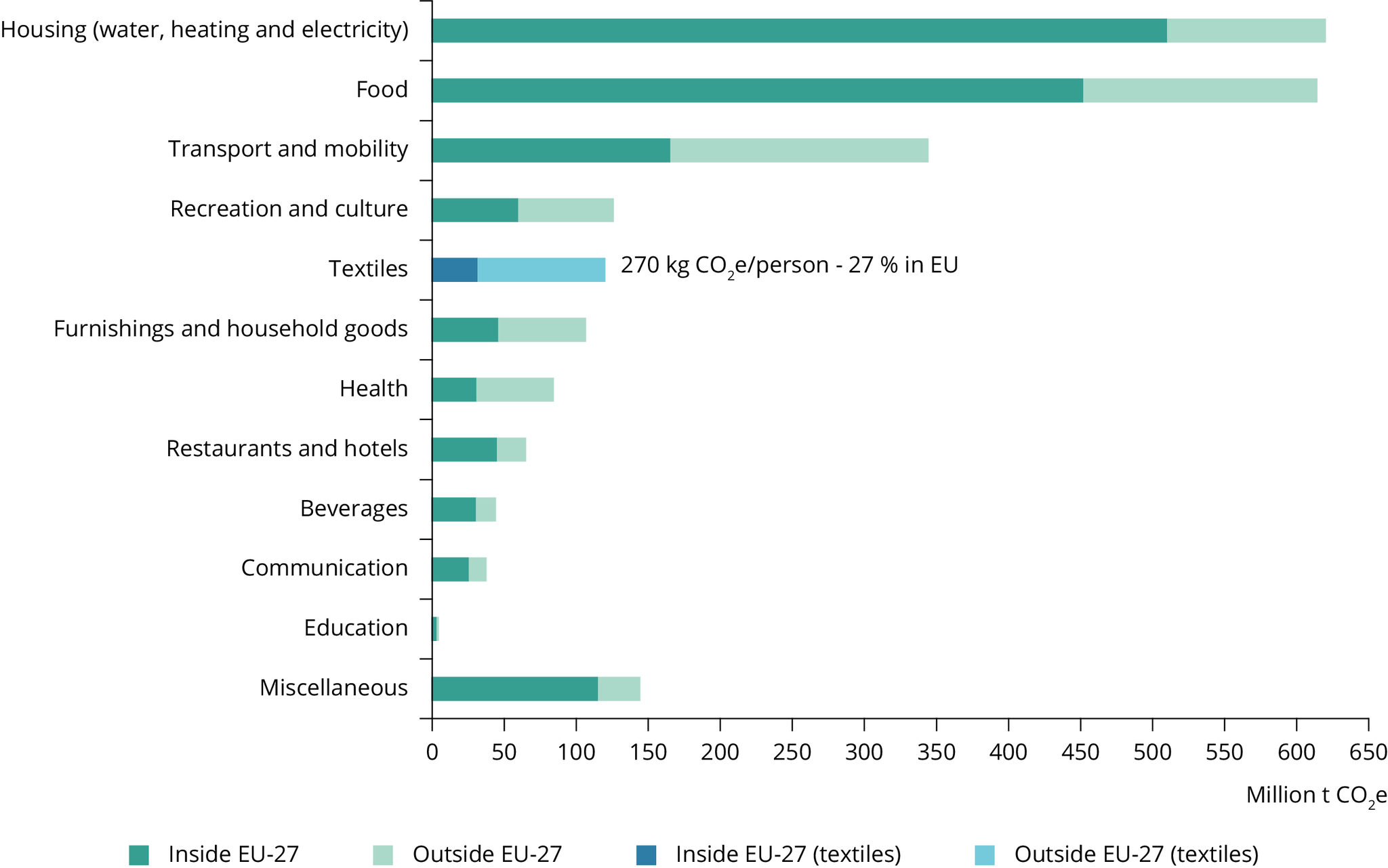

The response to the COVID-19 pandemic, involving stay-at-home measures and the closure of companies and shops, decreased textile production and demand overall (Euratex, 2021). As a result, the consumption of clothing and footwear per person decreased in 2020, relative to 2019, while the consumption of household textiles slightly increased. Average textile consumption per person amounted to 6.0kg of clothing, 6.1kg of household textiles and 2.7kg of shoes in 2020 (see Figure 1).

Source: EEA and European Topic Centre on Circular Economy and Resource Use.

Apart from this COVID-related drop in consumption in 2020, the estimated consumption of clothing and footwear stayed relatively constant over the last decade, with slight fluctuations between years (see Figure 2). Similarly, the consumption of household textiles was also relatively steady, with a slight increase over the decade.

Note: Calculated as production + import - export.

Sources: EEA and European Topic Centre for Circular Economy and Resource Use, based on Eurostat, (2021a).

More info...

When calculating the ‘estimated consumption’ based on production and trade data from 2020, and excluding industrial/technical textiles and carpets, total textile consumption is 15kg per person per year, consisting of, on average:

- 6.0kg of clothing

- 6.1kg of household textiles

- 2.7kg footwear.

For 2020, this amounts to a total consumption of 6.6 million tonnes of textile products in Europe. Textile consumption estimates are uncertain, as they vary by study, often using different scopes and calculation methods.

2. Environmental and climate impacts of textiles

The production and consumption of textiles has significant impacts on the environment and climate change. Environmental impacts in the production phase result from the cultivation and production of natural fibres such as cotton, hemp and linen (e.g. use of land and water, fertilisers and pesticides) and from the production of synthetic fibres such as polyester and elastane (e.g. energy use, chemical feedstock) (ETC/WMGE, 2021b). Manufacturing textiles requires large amounts of energy and water and uses a variety of chemicals across various production processes. Distribution and retail are responsible for transport emissions and packaging waste.

During use and maintenance — washing, drying and ironing — electricity, water and detergents are used. Chemicals and microfibres are also emitted into the waste water. Meanwhile, textiles contribute to significant amounts of textile waste. At the end of their life, textiles often end up in general waste and are incinerated or landfilled. When textile waste is collected separately, textiles are sorted and reused, recycled or disposed of, depending on their quality and material composition. In 2017, it was estimated that less than 1% of all textiles worldwide are recycled into new products (Ellen MacArthur Foundation, 2017).

To illustrate the magnitude of the impacts of textile consumption on raw material use, water and land use and greenhouse gas emissions compared with other consumption categories, we have updated our calculations of the life cycle environmental and climate impacts in the EU. We used input-output modelling based on data from the Exiobase database and Eurostat. In line with the reduced textile consumption level in 2020 because of the COVID-19 pandemic, the environmental impacts decreased from 2019 to 2020.

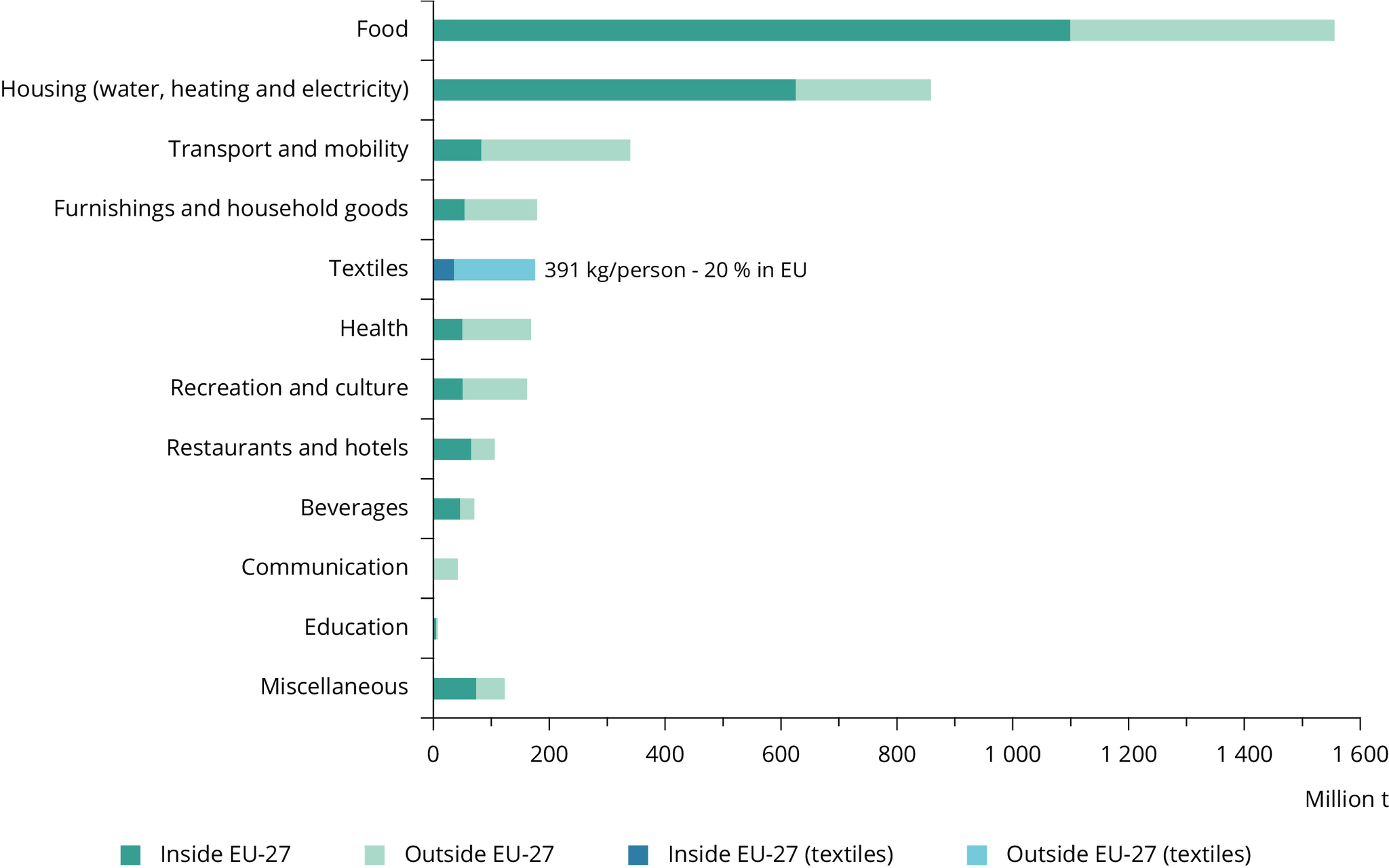

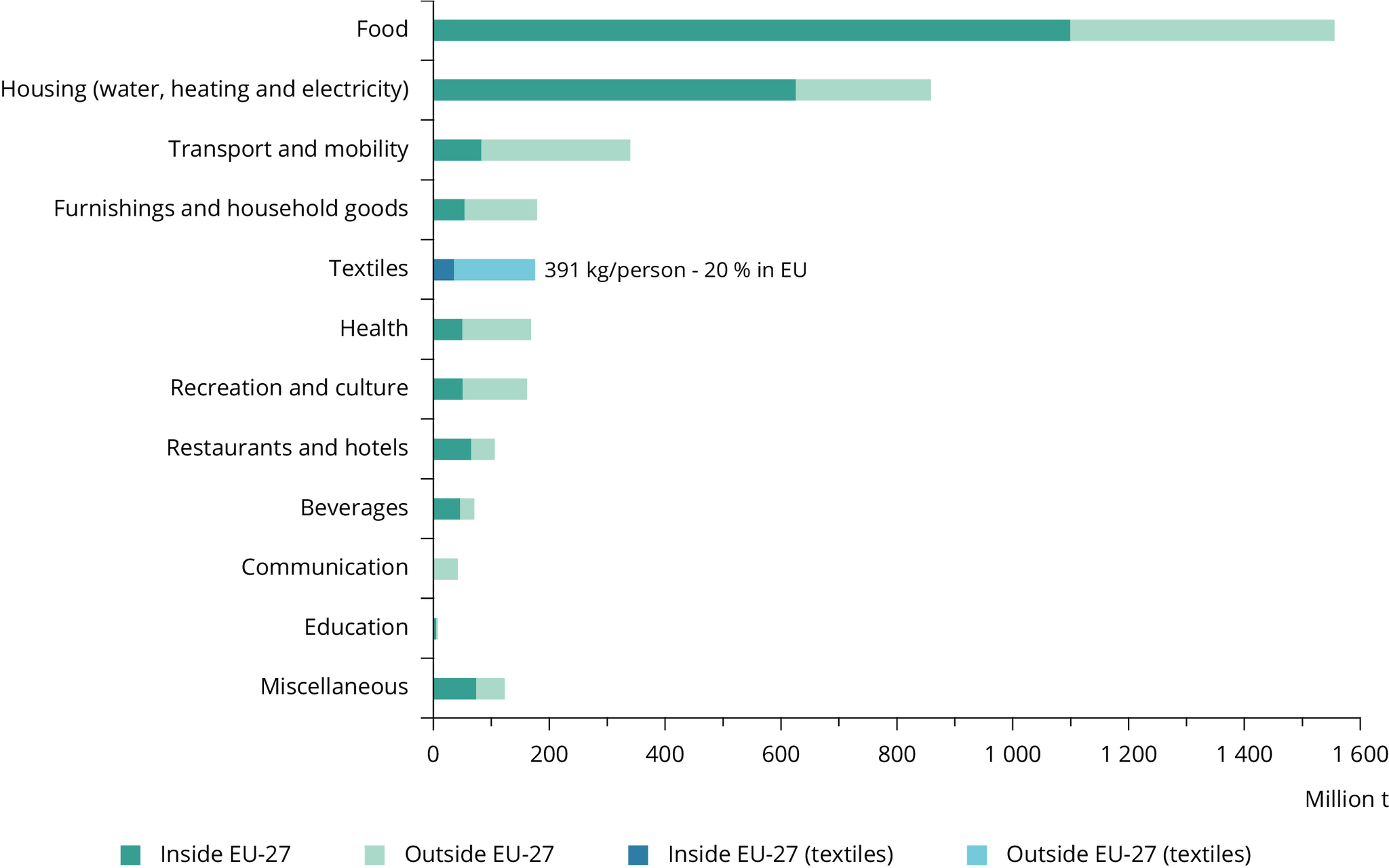

Raw material use

Large amounts of raw materials are used for textile production. To produce all clothing, footwear and household textiles purchased by EU households in 2020, an estimated 175 million tonnes of primary raw materials were used, amounting to 391kg per person. Roughly 40% of this is attributable to clothes, 30% to household textiles and 30% to footwear. This ranks textiles as the fifth highest consumption category in Europe in terms of primary raw material use (see Figure 3).

The raw materials used include all types of materials used in producing natural and synthetic fibres, such as fossil fuels, chemicals and fertilisers. It also includes all building materials, minerals and metals used in the construction of production facilities. Transport and retail of the textile products are included as well. Only 20% of these primary raw materials are produced or extracted in Europe, with the remainder extracted outside Europe. This shows the global nature of the textiles value chain and the high dependency of European consumption on imports. This implies that 80% of environmental impacts generated by Europe’s textile consumption takes place outside Europe. For example, cotton farming, fibre production and garment construction mostly take place in Asia (ETC/WMGE, 2019).

Source: EEA and European Topic Centre for Circular Economy and Resource Use, based on Exiobase v3.8.1.

More info...

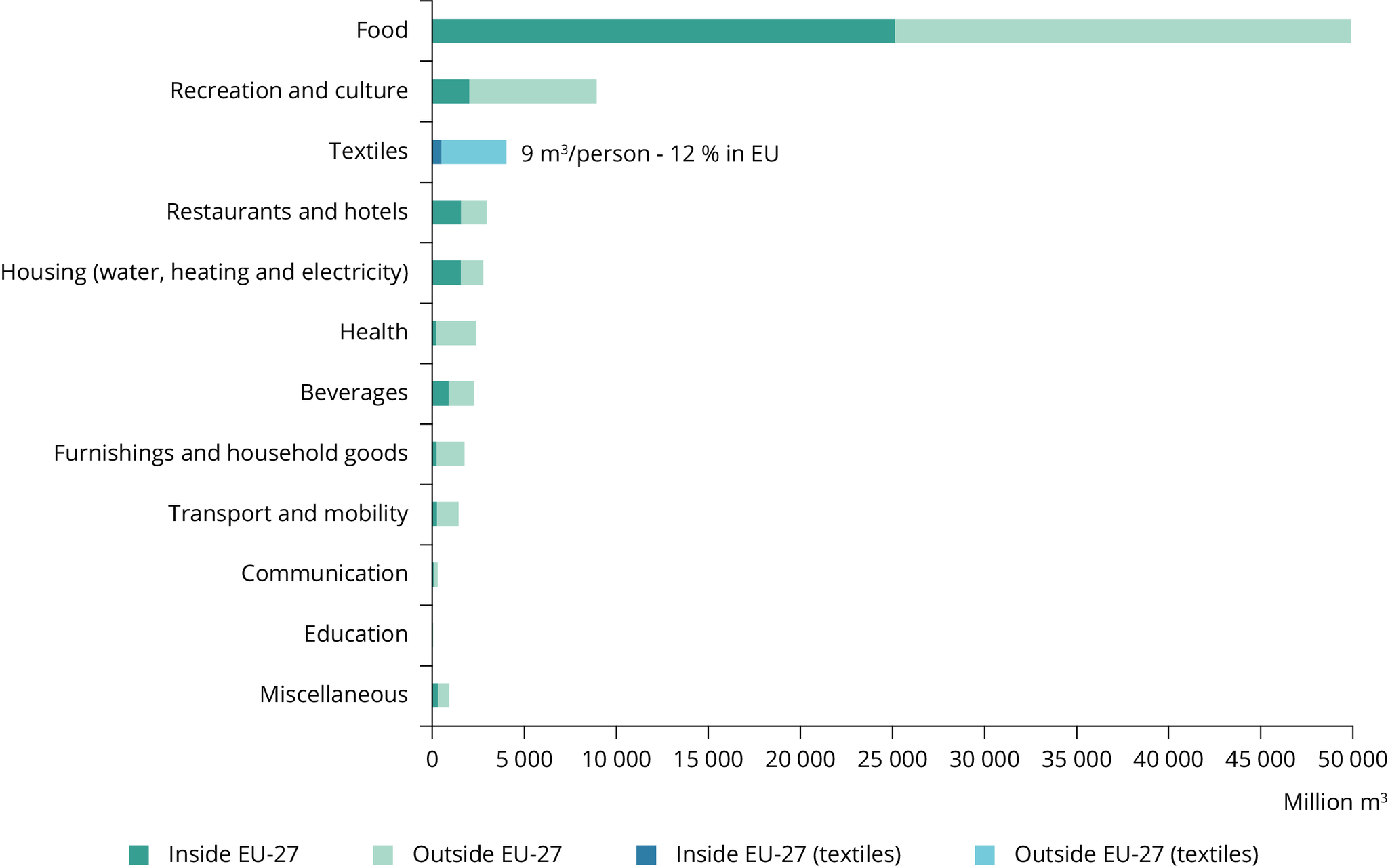

Water use

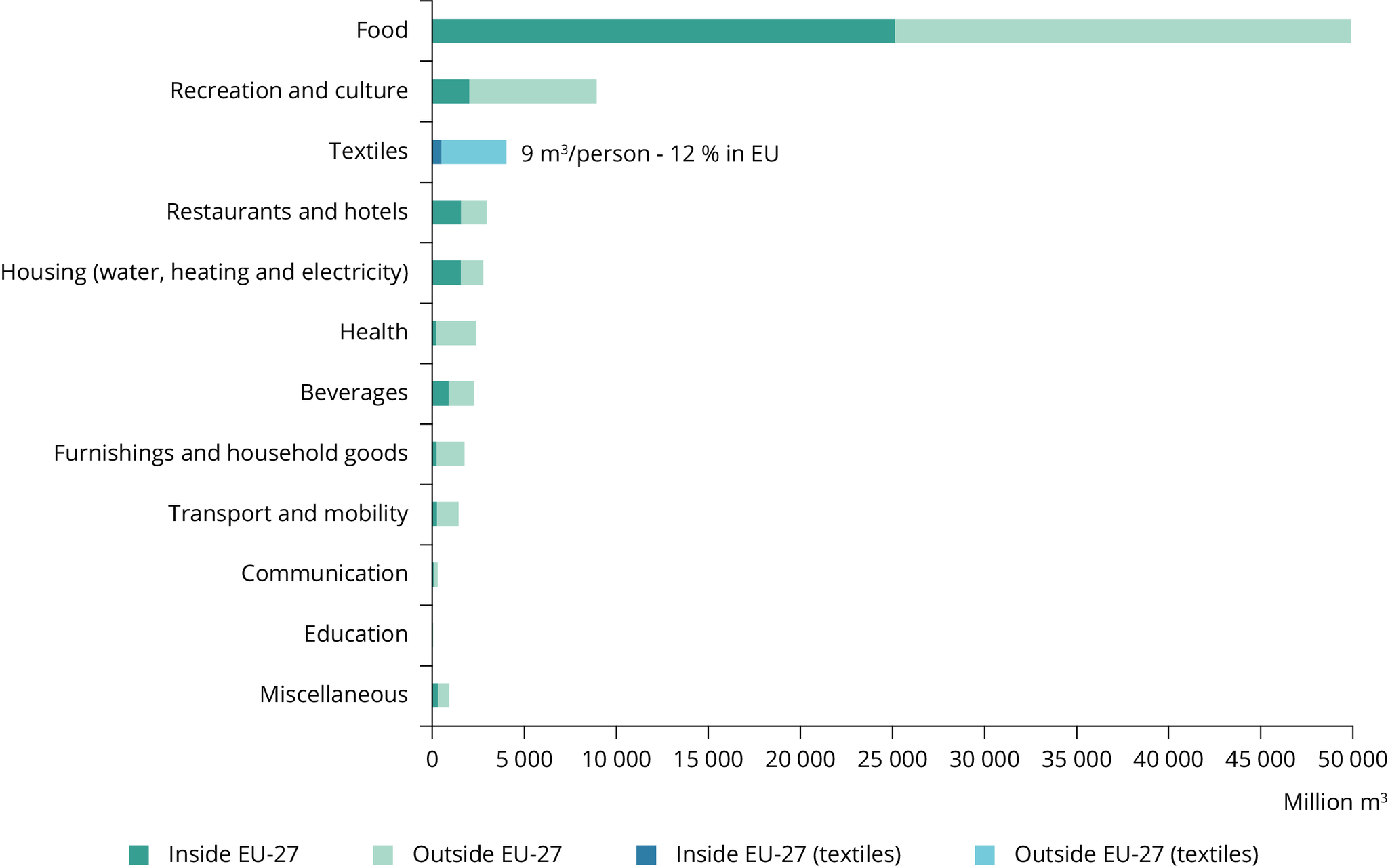

Producing and handling textiles requires large quantities of water. Water use distinguishes between ‘blue’ water (surface water or groundwater consumed or evaporated during irrigation, industry processes or household use) and ‘green’ water (rain water stored in the soil, typically used to grow crops) (Hoekstra et al., 2012).

To produce all clothing, footwear and household textiles purchased by EU households in 2020, about 4,000 million m³ of blue water were required, amounting to 9m³ per person, ranking textiles’ water consumption in third place, after food and recreation and culture (see Figure 4).

Additionally, about 20,000 million m³ of green water was used, mainly for producing cotton, which amounts to 44m³ per person. Blue water is used fairly equally in producing clothing (40%), footwear (30%) and household and other textiles (30%). Green water is mainly consumed in producing clothing (almost 50%) and household textiles (30%), of which cotton production consumes the most.

Source: EEA and European Topic Centre on Circular Economy and Resource Use, based on Exiobase v3.8.1.

More info...

Water consumption for textiles consumed in Europe mostly takes place outside Europe. It is estimated that producing 1kg of cotton requires about 10m³ of water, typically outside Europe (Chapagain et al., 2006).

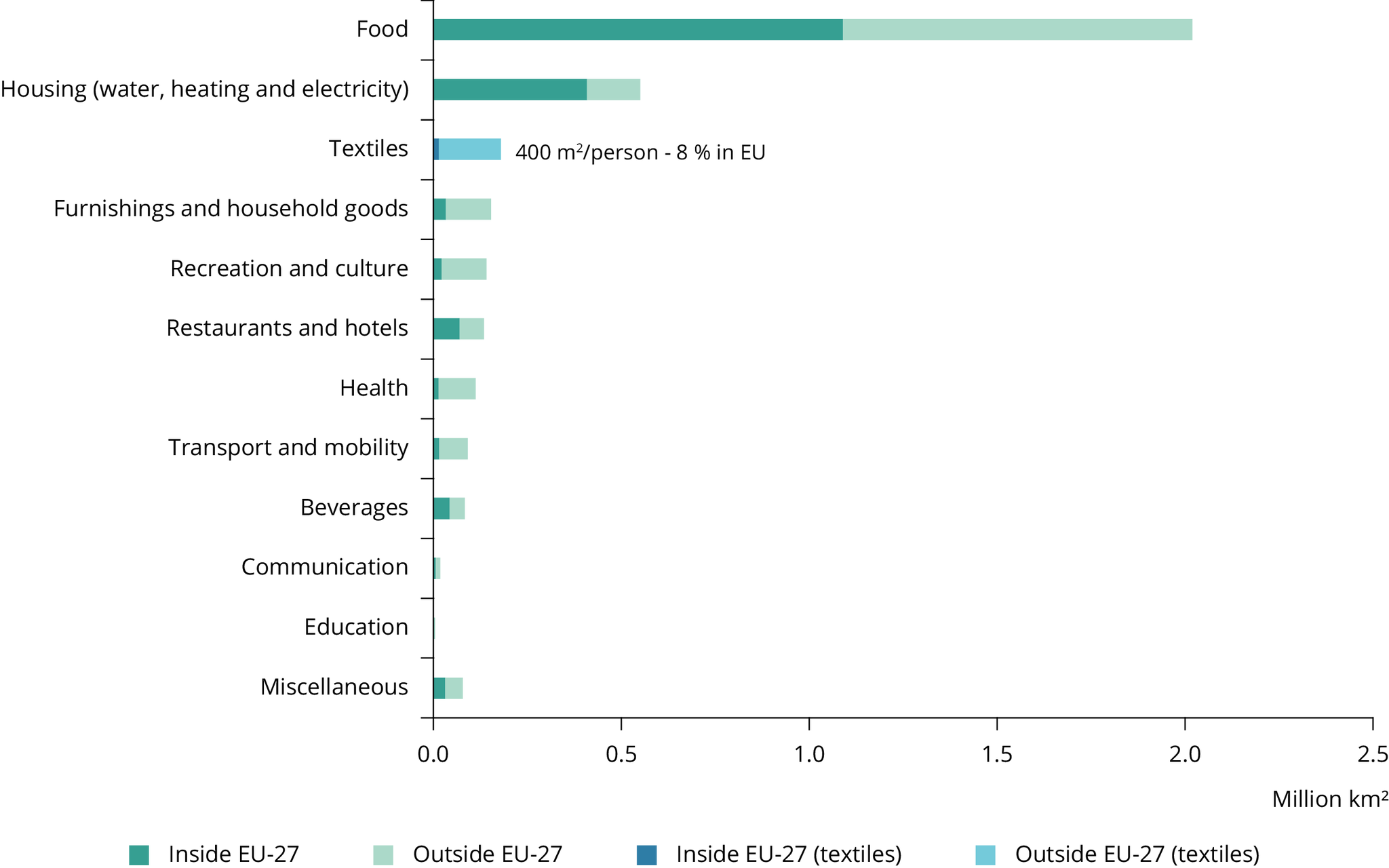

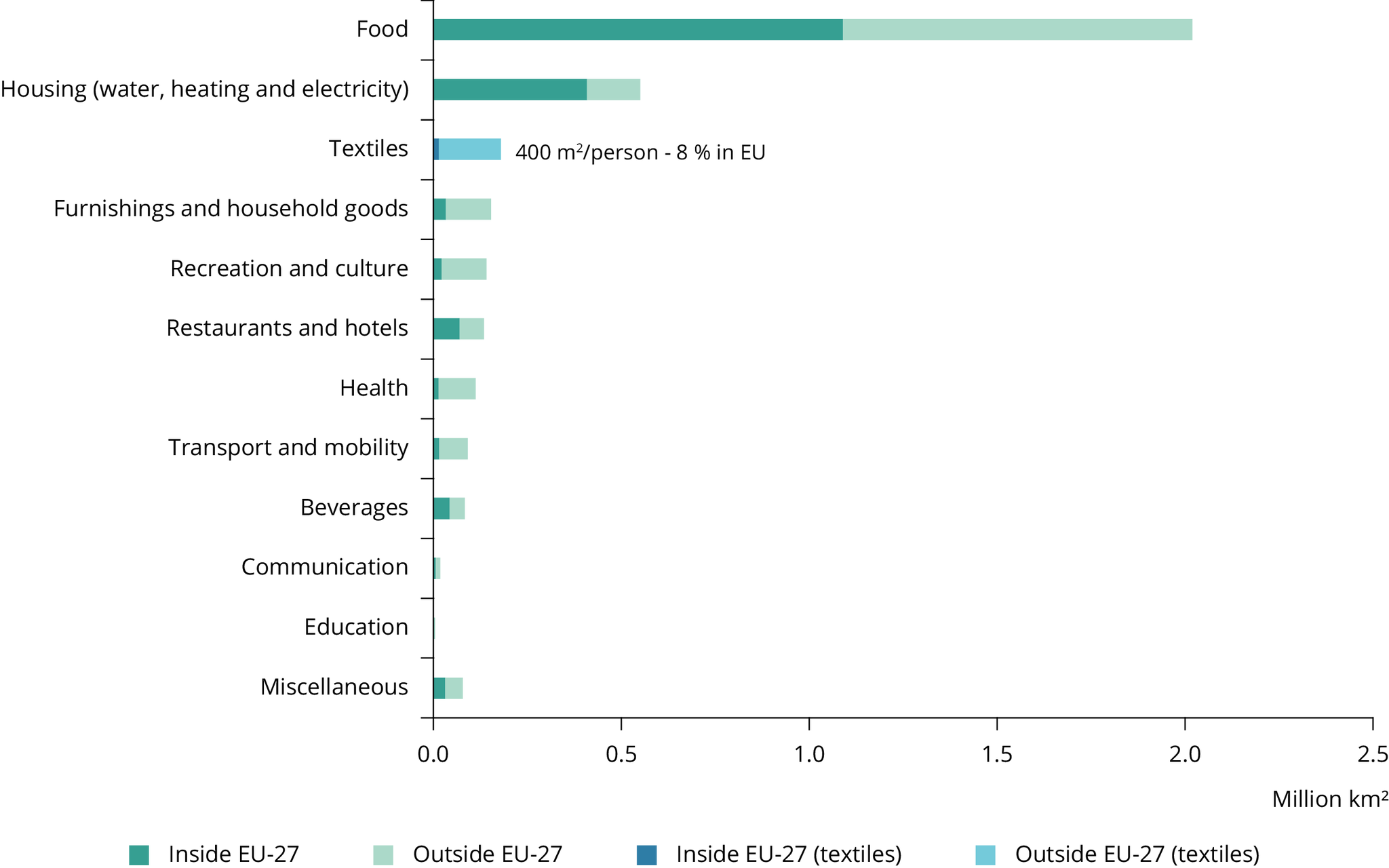

Land use

Producing textiles, in particular natural textiles, requires large amounts of land. The land used in the supply chain of textiles purchased by European households in 2020 is estimated at 180,000 km², or 400m² per person. Only 8% of the land used is in Europe. Over 90% of the land use impact occurs outside Europe, mostly related to (cotton) fibre production in China and India (ETC/WMGE, 2019). Animal-based fibres, such as wool, also have a significant land use impact (Lehmann et al., 2018). This makes textiles the sector with the third highest impact on land use, after food and housing (see Figure 5). Of this, 43% is attributable to clothes, 35% to footwear (including leather shoes, which have a high land use impact because of the need for cattle pasture) and 23% to household and other textiles.

Source: EEA and European Topic Centre for Circular Economy and Resource Use, based on Exiobase v3.8.1.

More info...

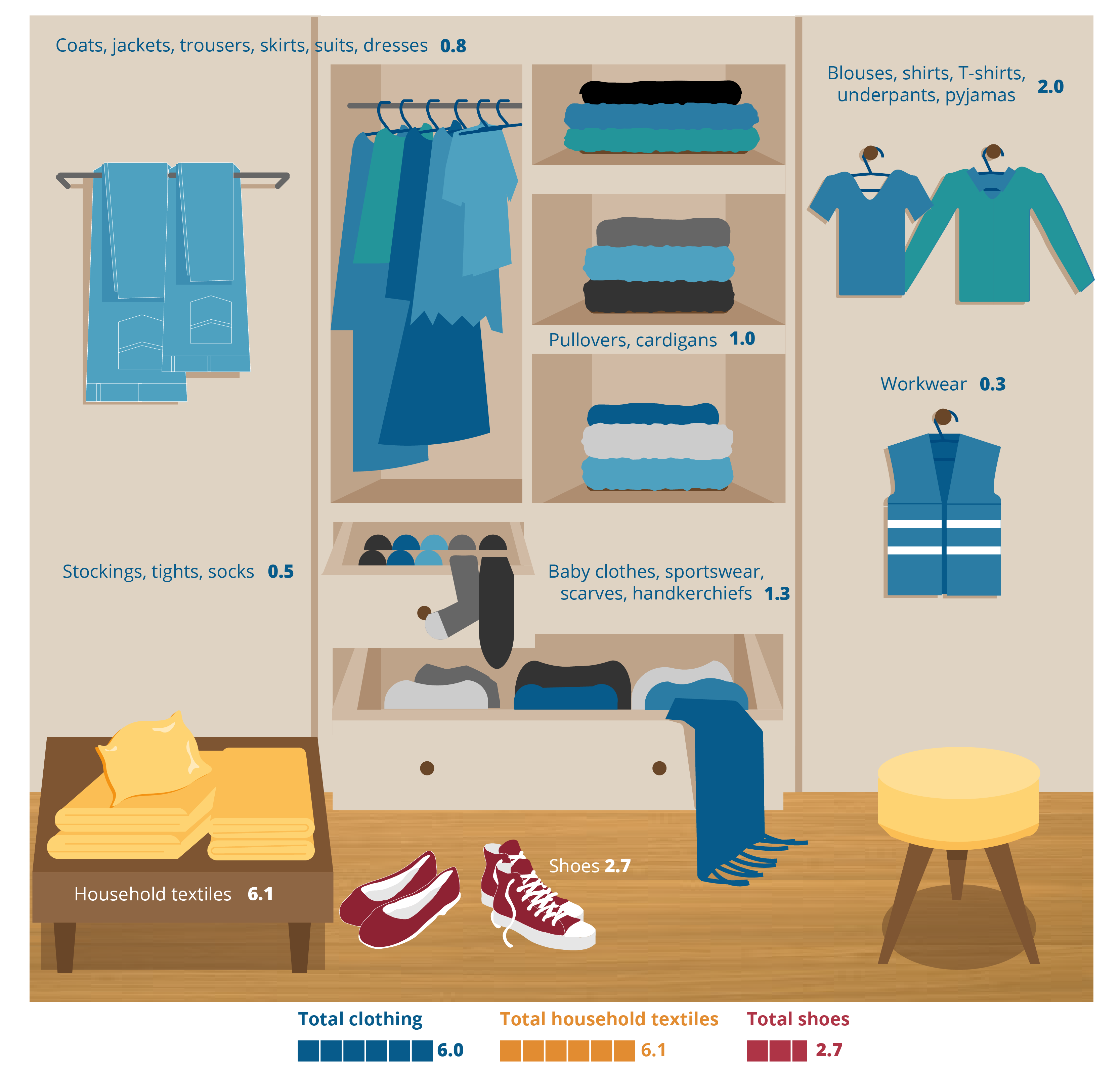

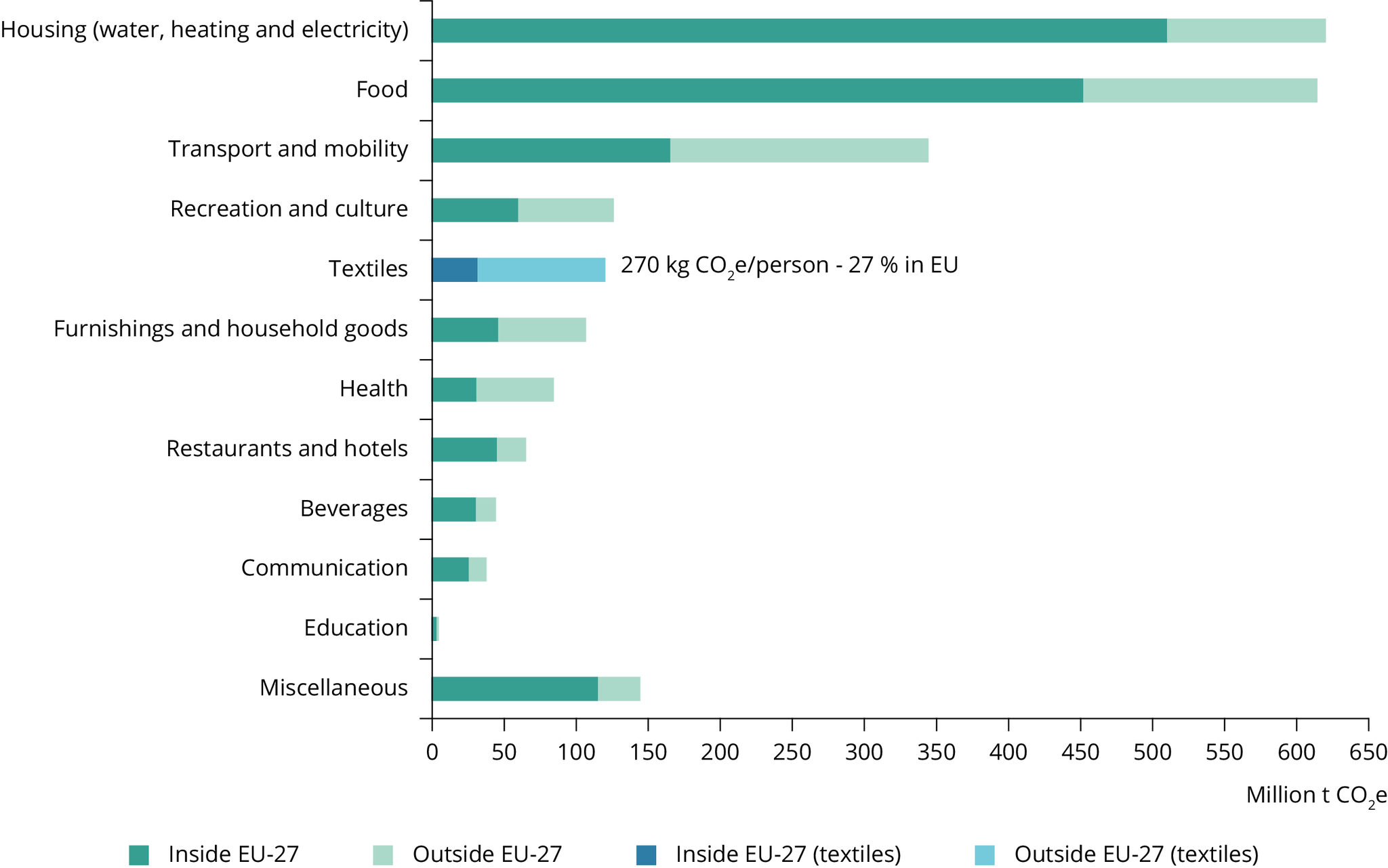

Greenhouse gas emissions

The production and consumption of textiles generate greenhouse gas emissions, in particular from resource extraction, production, washing and drying, and waste incineration. In 2020, producing textile products consumed in the EU generated greenhouse gas emissions of 121 million tonnes carbon dioxide equivalent (CO2e) in total, or 270kg CO2e per person. This makes textiles the household consumption domain responsible for the fifth largest impact on climate change, after housing, food, transport and mobility, and recreation and culture (see Figure 6). Of this, 50% is attributable to clothes, 30% to household and other textiles, and 20% to footwear. While greenhouse gas emissions have a global effect, almost 75% are released outside Europe, mainly in the important textile-producing regions in Asia (ETC/WMGE, 2019).

Source: EEA and European Topic Centre for Circular Economy and Resource Use, based on Exiobase v3.8.1.

More info...

About 80% of the total climate change impact of textiles occurs in the production phase. A further 3% occurs in distribution and retail, 14% in the use phase (washing, drying and ironing), and 3% during end of life (collection, sorting, recycling, incineration and disposal) (ECOS, 2021; Östlund et al., 2020).

Textiles made from natural fibres, such as cotton, generally have the lowest climate impact. Those made from synthetic fibres (especially nylon and acrylic) generally have a higher climate impact because of their fossil fuel origin and the energy consumed during production (ETC/WMGE, 2021b; Beton et al., 2014).

3. Design as an enabler of circular business models for textiles

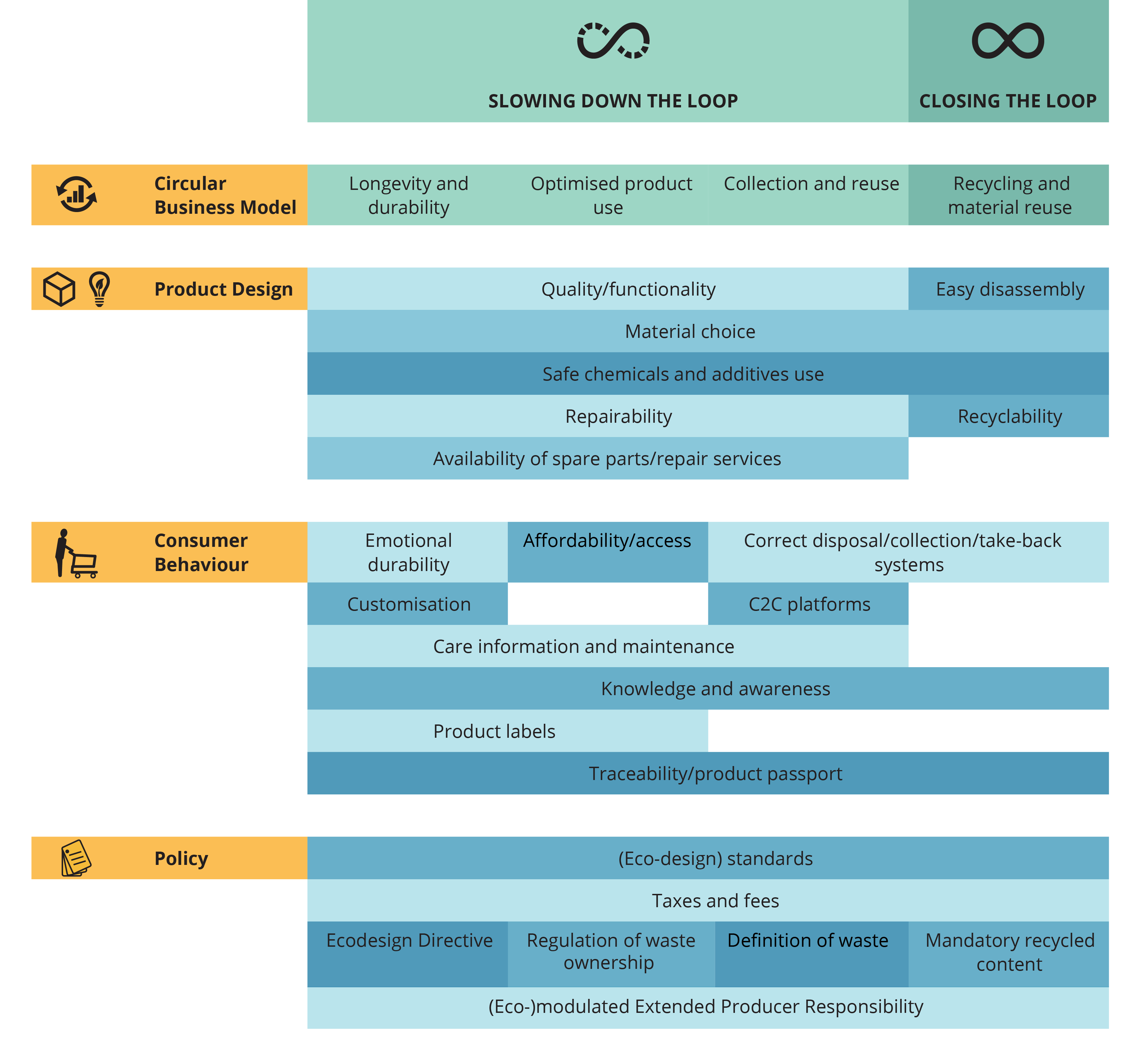

To reduce the environmental and climate change impacts of textiles, shifting towards circular business models is crucial to save on raw materials, energy, water and land use, emissions and waste (ETC/WMGE, 2019). Implementing and scaling circular business models requires technical, social and business model innovation; as well as enablers from policy, consumption and education (EEA, 2021).

Circular design is an important component of circular business models for textiles. It can ensure higher quality, longer lifetimes, better use of materials, and better options for reuse and recycling. While it is important to enable the recycling and reuse of materials, life-extending strategies, such as design for durability, ease of reuse, repair and remanufacturing, should be prioritised. Preventing the use of hazardous chemicals and limiting toxic emissions and release of microplastics at all life cycle stages should be incorporated into product design.

Designing for circularity is the most recent development in design for sustainability. Expanding a technical and product-centric focus to a focus on large-scale system-level changes (considering both production and consumption systems) shows that this latest development requires many more disciplines than traditional engineering design. Product design as a component of a circular business model depends on consumer behaviour and policy to realise its potential and enable implementation. Figure 7 shows the linkages between the circular business model, product design, consumer behaviour and policy. All are needed to slow down and close the loop, making it circular.

Source: EEA and European Topic Centre for Circular Economy and Resource Use; illustration by CSCP.

Below we discuss circular business model pathways that could support the shift towards a circular textiles system and how the design phase plays a critical role in each of these. The circular business model should focus on longevity and durability, optimised resource use, collection and reuse, and recycling and material use.

Longevity and durability

The first pathway to circularity is to ensure the longevity and durability of textile products through circular design. Increasing durability allows longer use and reuse of products, contributing to extending the life cycle of textiles. Fast-changing fashion trends and a decrease in product quality have reduced the life span of clothes. Over the last 20 years, the use time of clothes decreased by 36%, with each garment used an average of seven or eight times (Lujan-Ornelas et al., 2020; Ellen MacArthur Foundation, 2017). This pathway requires a shift to circular business models that support longer product use and to more sustainable purchasing behaviours and lifestyles.

At the design stage, careful selection of materials increases the longevity, durability and repairability of textiles. The materials used determine the potential to keep the product in use for longer and the ease of repair. Several underlying design principles increase the durability and quality of garments, including technical requirements for colour fastness and fabric resistance, and practical requirements that clothes are multifunctional and fit for purpose and that repair kits and/or spare parts are available.

Circular design principles are important for product longevity and durability because 40% of all reasons for consumers discarding clothes are linked to (functional) changes of garments (Laitala et al., 2015), including:

- a hole or tear

- worn-out appearance

- loss of elasticity or shape

- stains

- colour changing or fading.

In addition to introducing durable and eco-friendly materials, it is important to bring about behavioural changes in consumers. Here, the focus should be on timeless design (slow fashion) to counter fast-moving fashion trends, and on providing product care information and offering repair services (e.g. in-store repair in retailers or partnerships with local repair shops). All aspects could play an important role in fostering the consumer’s emotional connection with garments and their appreciation of them.

In addition to behavioural and educational enablers, policy enablers are needed to support longevity and durability. They include eco-design requirements, harmonised extended producer responsibility schemes, economic instruments (such as taxes on certain uses of unwanted materials) and support for desirable production processes (ETC/WMGE, 2019, 2021a; EuRIC, 2020; OECD, 2017).

Optimised resource use

The second pathway is optimising resource use to reduce pressures. Companies in the textiles sector are focusing on reducing and optimising water and energy use, air emissions and water pollution by using safe chemicals and diversified biodegradable materials. In recent years, the circular economy transition has led some parts of the textile industry to the introduction of business models that promote access to products over ownership. Access-based business models have the potential to increase the use of products while reducing the use of new materials and textile waste (EEA, 2021; ETC/WMGE, 2021a).

At the production stage, eco-design principles have been identified to optimise resource use. These include reducing emissions, waste and inputs such as water, chemicals and energy, and producing fibres from renewable sources and/or recycled content. Design requirements certifying a minimum content of recycled material could also optimise resource use. Less than 1% of textile waste is recycled into new fibres for clothing. The non-reusable fraction is mostly downcycled into industrial rags, upholstery filling and insulation or is incinerated or landfilled (Pappas, 2021). Design requirements could also indirectly increase the collection of materials for reuse and recycling and potentially bring new sorting and waste recovery streams.

Some companies offer clothing subscription services, in which customers pay a fee to rent a specific number of garments. This allows them to change their wardrobe frequently, without acquiring new clothes. To fulfil the potential of these business-to-consumer models, consumers need to see them as viable alternatives to traditional purchases. However, the extent to which these models perpetuate the desire for ever-changing wardrobes, underpinning unsustainable levels of consumption and production, needs to be carefully assessed.

Several international certifications and labels have already paved the way for optimising resource use. However, to decouple profit generation from resource use, alternative ownership models, such as clothing subscription services and leasing models, need to be supported by policy. These policy enablers then need to support the successful adoption of access-based business models, define regulations on ownership, transport and trade of textiles (including waste streams) and promote regulatory incentives (such as VAT reductions or extended producer responsibility).

Collection and reuse

The third pathway in which design plays a role is the collection and reuse of textiles. Circular business models built around the collection and resale of textiles aim to extend their life beyond the first user (EEA, 2021). Currently, only about 20% of consumers regularly buy pre-owned clothes, according to a 2020 ING survey (ING, 2020). Online platforms for buying and selling clothes are increasingly popular, and some brands and retailers have introduced take-back services and pre-loved collections. The success of these alternative business models depends on factors such as brand image and the style and quality of products (Hemkhaus et al., 2019). Moreover, the product type has an impact on the potential for reuse. For example, baby’s and children’s clothes are typically used for only a short time and are often sold in second-hand shops and on online platforms. Similarly, luxury brands and designer and vintage pieces are often sold for reuse (ETC/WMGE, 2021a).

Understanding consumers’ behaviour and their attitude and motivation to the disposal of textiles is important, so that collection schemes and selling platforms are set up in ways that work. Companies need to tell customers what happens to the textiles collected. This motivates them to participate, while transparency also helps to prevent corporate greenwashing. There is a risk that increasing the collection of reused clothes encourages more consumption of new resources, as consumers free up space in their wardrobes (ETC/WMGE, 2021a; Köhler et al., 2021).

To successfully adopt circular business models that enable collection and reuse, specific regulations on the transport and trade of collected textiles are necessary. Targets and regulatory incentives for reuse activities and extended producer responsibility schemes are ways forward that support investment in collection, reuse and recycling capacities (ECOS, 2021; ETC/WMGE, 2021a).

Recycling and material reuse

While the previous pathways focused on ‘slowing down the loop’, the last pathway on recycling and material reuse ‘closes the loop’. By reducing resource use and prolonging the useful life of textiles, this model enables the loop to be closed by turning waste textiles into raw material for new textiles or other production chains. Material can be reused at the fabric level through remanufacturing, also often referred to as ‘upcycling’, or at the fibre level through recycling. Both reduce the need for virgin raw materials and textile waste generation (EEA, 2021).

Despite interest from a range of stakeholders, the recyclability of textiles is rarely considered in the design process (Watson et al., 2017). Because of specific functional needs (e.g. stretchiness), aesthetic reasons (e.g. use of prints or layers) or economic reasons (e.g. mixing natural fibres with less expensive synthetic fibres), other considerations in the design process are often given priority over design for recycling. This results in almost one third of all textile waste being unsuitable for fibre-to-fibre recycling (Köhler et al., 2021). Likewise, textile products containing (non-removable) buttons, zippers or other accessories are difficult to recycle. In order not to interfere with recycling or create additional waste streams, trims and accessories should be easily removed. Textile products should be labelled with the materials and chemicals they contain and whether they are pure or mixed, as textile recycling processes have different input requirements. This helps prevent toxic chemicals from recirculating (Bauer et al., 2018; Ellen MacArthur Foundation, 2021; Köhler et al., 2021).

Designing and making a product for recycling is effective only if the loop is actually closed. Although there are no figures for all EU countries, the collection rate of used textiles in the EU varies significantly from 4.5% in Latvia to 45% in the Netherlands (Köhler et al., 2021). This means that the majority of used clothing and household textiles are still disposed of in mixed municipal waste streams. Mandatory collection of textiles will be introduced in the EU in 2025.

Possible areas for enhancing the recycling rate of textiles include:

- policy support in the form of tax incentives for textile products containing recycled content

- tax penalties on conventional products

- extended producer responsibility schemes.

These policies would contribute to internalising the environmental costs of virgin fibres and effectively give recycled fibres and material reuse an economic advantage. This would encourage manufacturers to apply design for recycling in their operations, as it would be coupled with a bonus-malus system to reflect circular characteristics such as durability, reuse, repairability and recyclability (ECOS, 2021; Köhler et al., 2021; ETC/WMGE, 2021a).

References

Bauer, B., et al., 2018,Potential ecodesign requirements for textiles and furniture, Nordic Council of Ministers, Copenhagen.

Beton, A., et al., 2014, Environmental improvement potential of textiles (IMPRO Textiles), Publications Office of the European Union, Luxembourg, accessed 24 March 2020.

Chapagain, A. K., et al., 2006, ‘The water footprint of cotton consumption: an assessment of the impact of worldwide consumption of cotton products on the water resources in the cotton producing countries’, Ecological Economics60(1), pp. 186-203 (DOI: 10.1016/j.ecolecon.2005.11.027).

ECOS, 2021, Durable, repairable and mainstream — how ecodesign can make our textiles circular, ECOS, accessed 30 August 2021.

EEA, 2021, A framework for enabling circular business models in Europe, EEA Briefing No 22/2020, European Environment Agency, accessed 31 May 2021.

Ellen MacArthur Foundation, 2017, A new textiles economy: redesigning fashion’s future, Ellen MacArthur Foundation, accessed 21 January 2022.

Ellen MacArthur Foundation, 2021, The jeans redesign guidelines 2021, Ellen MacArthur Foundation, accessed 22 September 2021.

ETC/WMGE, 2019, Textiles and the environment in a circular economy, Eionet Report No 6/2019, European Topic Centre for Waste and Materials in a Green Economy, accessed 26 March 2020.

ETC/WMGE, 2021a, Business models in a circular economy, Eionet Report No 2/2021, European Topic Centre on Waste and Materials in a Green Economy, accessed 26 November 2021.

ETC/WMGE, 2021b, Plastic in textiles: potentials for circularity and reduced environmental and climate impacts, Eionet Report No 1/2021, European Topic Centre on Waste and Materials in a Green Economy, accessed 28 April 2021.

Euratex, 2020, Facts & key figures of the European textile and clothing industry, Annual Report, European Apparel and Textile Confederation, accessed 5 June 2021.

Euratex, 2021, ‘2021 must be a turning point for the European textiles and clothing industry’, European Apparel and Textile Confederation, accessed 28 September 2021.

EuRIC, 2020, ‘EuRIC position on EPR schemes for textiles’, EuRIC, accessed 11 January 2022.

Eurostat, 2021a, ‘EU trade since 1988 by CPA 2.1 (DS-1062396)’, Eurostat Data Explorer, accessed 21 January 2022.

Eurostat, 2021b, ‘Final consumption expenditure of households by consumption purpose (COICOP 3 digit) (nama_10_co3_p3)’, Eurostat Data Explorer, accessed 21 January 2022.

Hemkhaus, M., et al., 2019, Circular economy in the textile sector, Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ), accessed 7 January 2022.

Hoekstra, A. Y., et al., 2012, The water footprint assessment manual, Earthscan, London.

ING, 2020, Learning from consumers: how shifting demands are shaping companies’ circular economy transition, ING, accessed 21 September 2021.

Köhler, A., et al., 2021, Circular economy perspectives in the EU textile sector: final report, Final Report, Publications Office of the European Union, Luxembourg, accessed 8 July 2021.

Laitala, K., et al., 2015, ‘Making clothing last: a design approach for reducing the environmental impacts’, International Journal of Design9(2), pp. 93-107.

Lehmann, M., et al., 2018, Pulse of the fashion industry 2018, Global Fashion Agenda and Boston Consulting Group () accessed 29 September 2021.

Lujan-Ornelas, C., et al., 2020, ‘A life cycle thinking approach to analyse sustainability in the textile industry: a literature review’, Sustainability12(23), p. 10193.

OECD, 2017, Behavioral insights and public policy lessons from around the world, Organisation for Economic Co-operation and Development, accessed 21 January 2022.

Östlund, A., et al., 2020, Investor brief: sustainability in textiles and fashion, Mistra Dialogue, Stockholm, accessed 30 August 2021.

Pappas, E., 2021, ‘Latest trend keeps clothes out of landfill’, Horizon — The EU Research and Innovation Magazine, accessed 7 January 2022.

Watson, D., et al., 2017, Stimulating textile-to-textile recycling, Nordic Council of Ministers, Copenhagen.

Identifiers

Briefing no. 01/2022

Title: Textiles and the environment: the role of design in Europe’s circular economy

HTML: TH-AM-22-001-EN-Q - ISBN: 978-92-9480-433-4 - ISSN: 2467-3196 - doi: 10.2800/006659

PDF: TH-AM-22-001-EN-N - ISBN: 978-92-9480-432-7 - ISSN: 2467-3196 - doi: 10.2800/578806

Document Actions

Share with others